What Are The Five Safety Precautions Use In Machine Workshop

Wear clothing suited for the job wear shoes with thick soles.

What are the five safety precautions use in machine workshop. Never use hands to remove chips and curls. Ignorance of the dangers of a machine or tool and of safety precautions. Wear shirts or uppers with sleaves cut off or rolled.

Not paying attention to safety rules. Unsuitable clothing Large loose clothing unbuttoned shirt wearing neckties. Adjust the upper guard assembly to within ¼ inch of the stock prior to starting the machine.

Machine Safety at Carleton. Types of Safety precautions while working in an industry workshop with tools and machines. Dont wear neck ties or loose turn clothing of any kind.

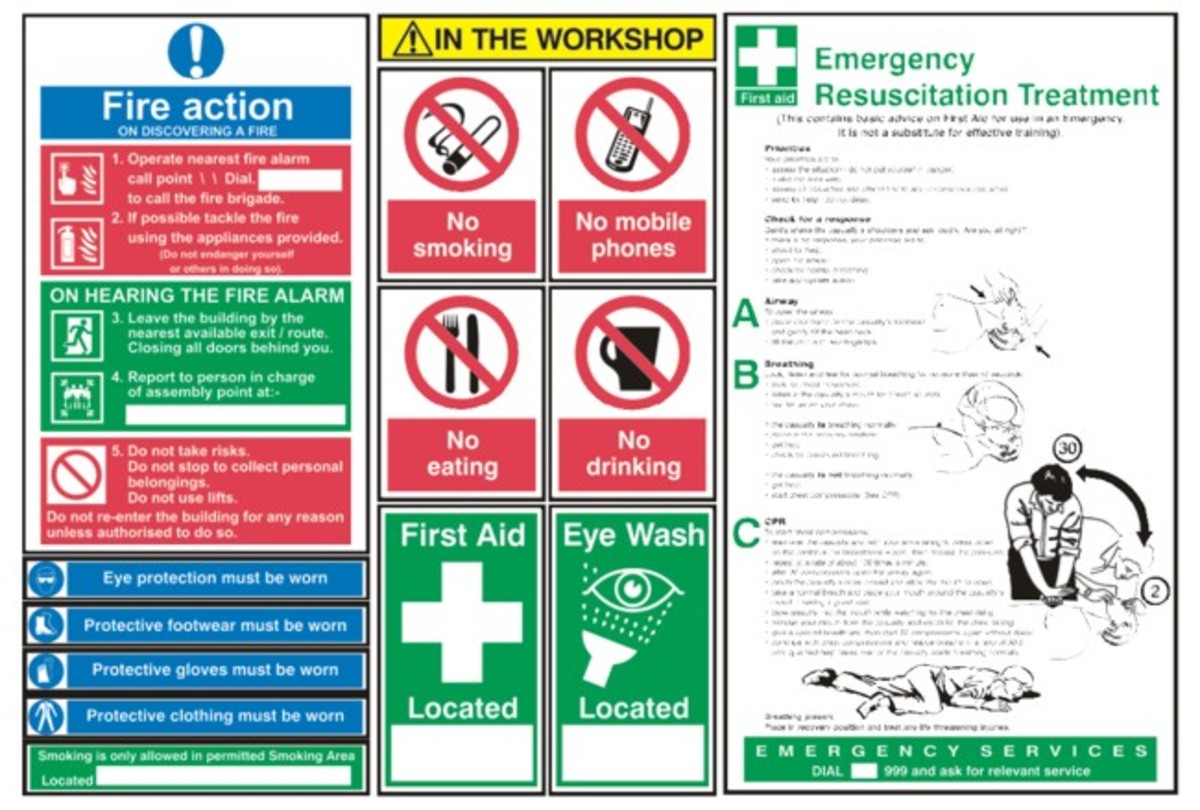

Specific safety guidelines for some of the machine process like lathe drilling shaping planning slotting grinding milling and finishing operations are also described in the following. It contains general advice on the precautions which you and your employer can take to avoid these risks. Always stop the machine for making measurements and adjustments.

Use the supplied chip brushes and rags to clean machinery. Always stop machine for cleaning chips and curls. They must be strictly followed for safety.

Safety precautions for Milling Machines. Health and Safety Executive Working safely with metalworking fluids A guide for employees 1 of 5 pages Introduction This leaflet aims to help employees who work with metalworking fluids understand the main risks to their health. Safety Precautions can be defined as measures taken in the workshop to avoid accident or harm which one may encounter in the workshop.