How To Sharpen Carbide Metal Lathe Tools

Trusted China Suppliers Verified by SGS.

How to sharpen carbide metal lathe tools. But considering the cost of carbide tools it makes sense to get the most use out of. In this video I explore different aspects a slow speed grinding. Using a sharp object mark a point roughly 23rds of the way across the top and 12 down the side.

It takes a special grinding wheel made of silicon carbide abrasive When I was an apprentice that is all the shop had and we used a lot of brazed on tools in the shop. Ad China Metal Lathe. So in short you can sharpen carbide lathe tools but it takes a little more effort and it wont make them quite as sharp as fresh inserts.

How to use a slow speed grinder to sharpen carbide tooling. Ad China Metal Lathe. This is easy to do using a diamond sharpening tool.

For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. They require a dimond stone because its the only material hard enough to properly sharpen carbide. Carbide does not lend itself well to offhand grinding although it can be ground that way.

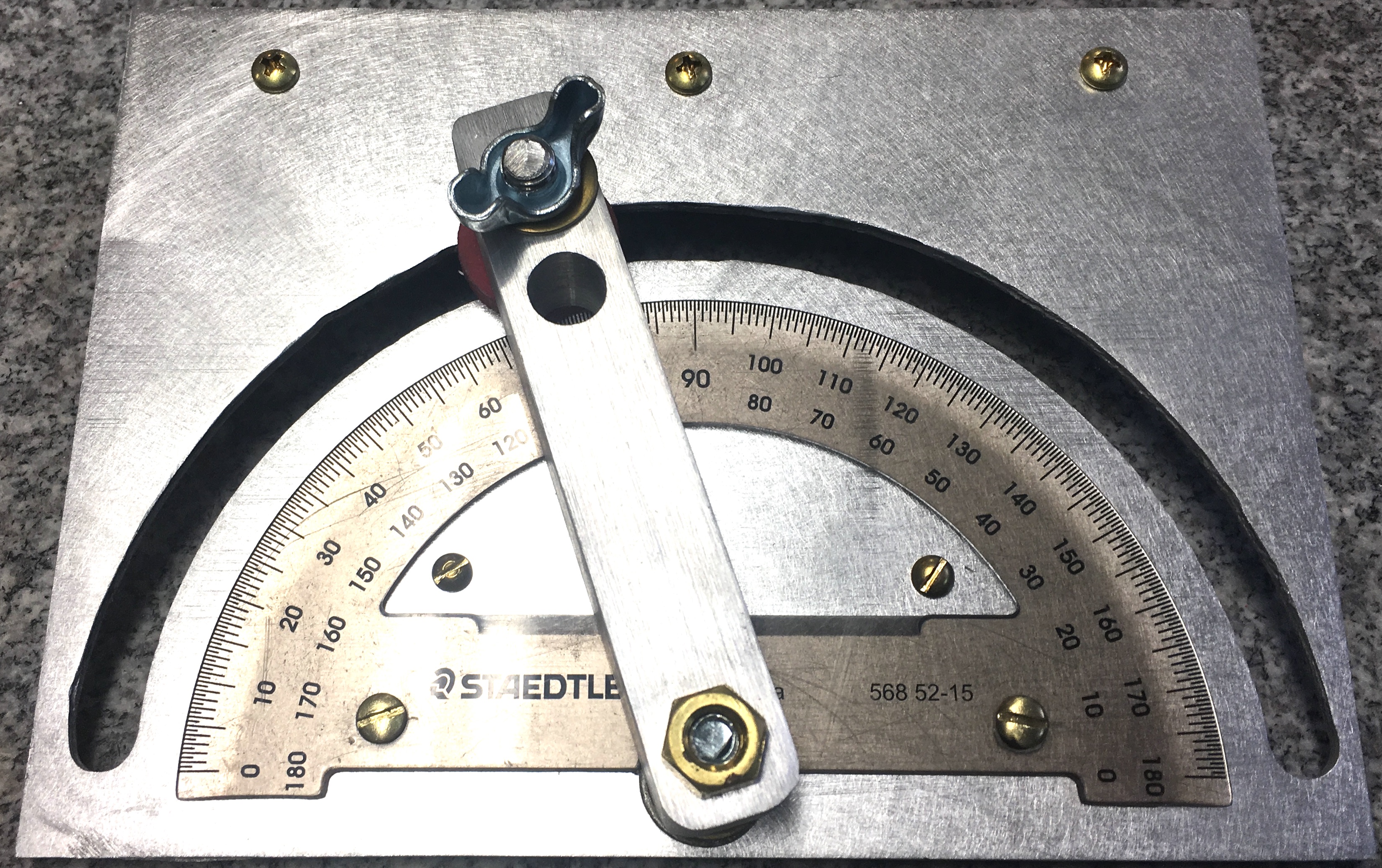

Without sharpening your machining. Positive rake will make your tools free cutting reducing deflection and power requirements. It is a sled which rides atop the SVD-110 Tool.

At present the commonly used grinding wheels are alumina and silicon carbide. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with. Carbide tools can be sharpened on an ordinary bench grinder but it does not do the best job in terms of finish.