How To Make Checkering Tools

Advanced checkering involves using a third checkering tool the w i d e spacing tool to make skip-line checkering google.

How to make checkering tools. Its best to start the job with a checkering panel pattern cut from a piece of white paper thinner than copy paper is better so a pattern appropriate for the particular stock undergoing surgery can be chosen - with an eye toward overall size and outlineshape. A single-line cutter is indispensable. Hand tool use is not eliminated however the time required to finish the job is dramatically reduced.

Once thats done its just a matter of moving across the surface one line at a time with the double-head tool. Cut an intersecting line at approximately 40 for the second master line. These tools handles are made of American walnut with tool shanks constructed of 18-inch square steel stock.

The cutters are attached to the tools shanks with a steel rollpin that slips through a hole in the tool shank and cutter. The MMC Rotary Tool will quickly produce cut checkering from 16-32 lines per inch. Like most forms of art practice is essential but in the hands of a trained craftsman.

Gunstock Finishing and Checkering Part 1 - TOOLSGunstock carving and checkering requires the use of specialized tools to get the job done. Hold the tang with a pair of pliers and heat the forward two inches of the file to a dull red. This is the most common type of checkering.

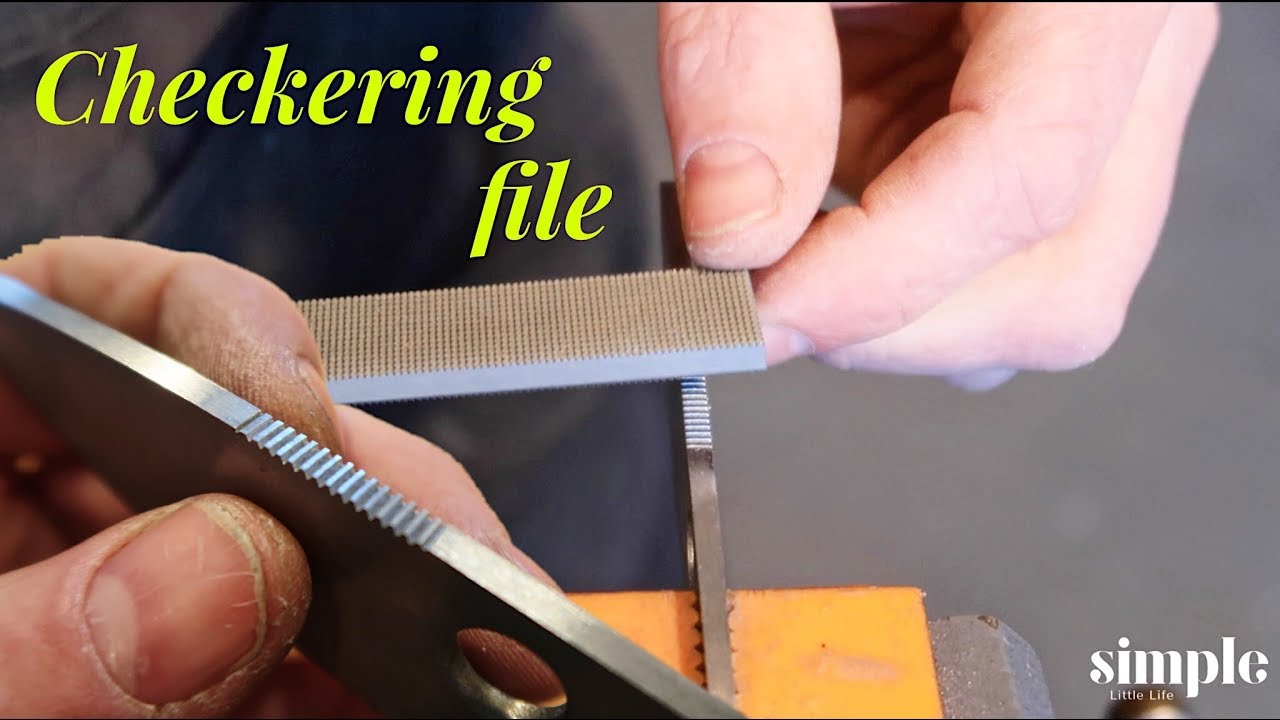

Next I make the two master lines within the pattern at a 45 degree angle or thereabouts and they are the starting point of the checkering. Using a mill bastard file to cut teeth. Cutting flat-top checkering requires a special tool.

In addition to our own line of tools we offer equipment and supplies from industry-leading brands like Grace USA Browning and DEM-BART. I made a sharp cutter from a piece of scrap steel to re-cut the line around the edge. Investing in electric checkering tools before learning the process can turn into a big waste of money if you decide that it simply isnt for you.