How Much Does It Cost To Start A Cnc Machine Shop

Either buy your mill new or carefully test a.

How much does it cost to start a cnc machine shop. Multi-axis machines are more expensive to run so will cost more. If not you will have to re-evaluate these expenses. You can find the Machine Hourly Rate Calculator on the Machine Profile under the Setup Basics tab.

It can report turnover of 300000 to millions. The study found that the characteristics of these higher performing CNC machine shops included gross sales that were 14 higher than other shops and median net income margin of 129 versus 59. The price for CNC milling machines often increases to accommodate the operators salary as well.

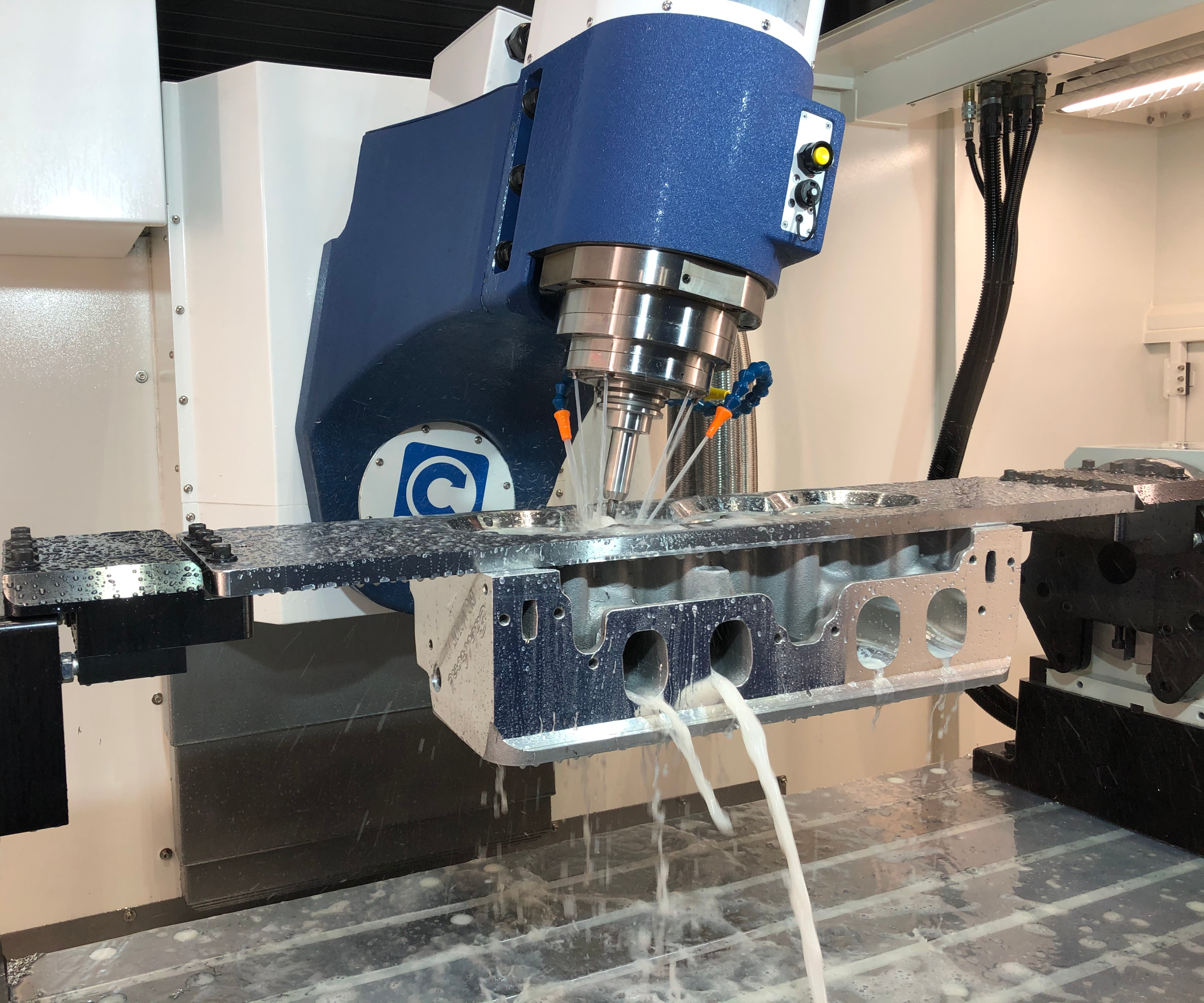

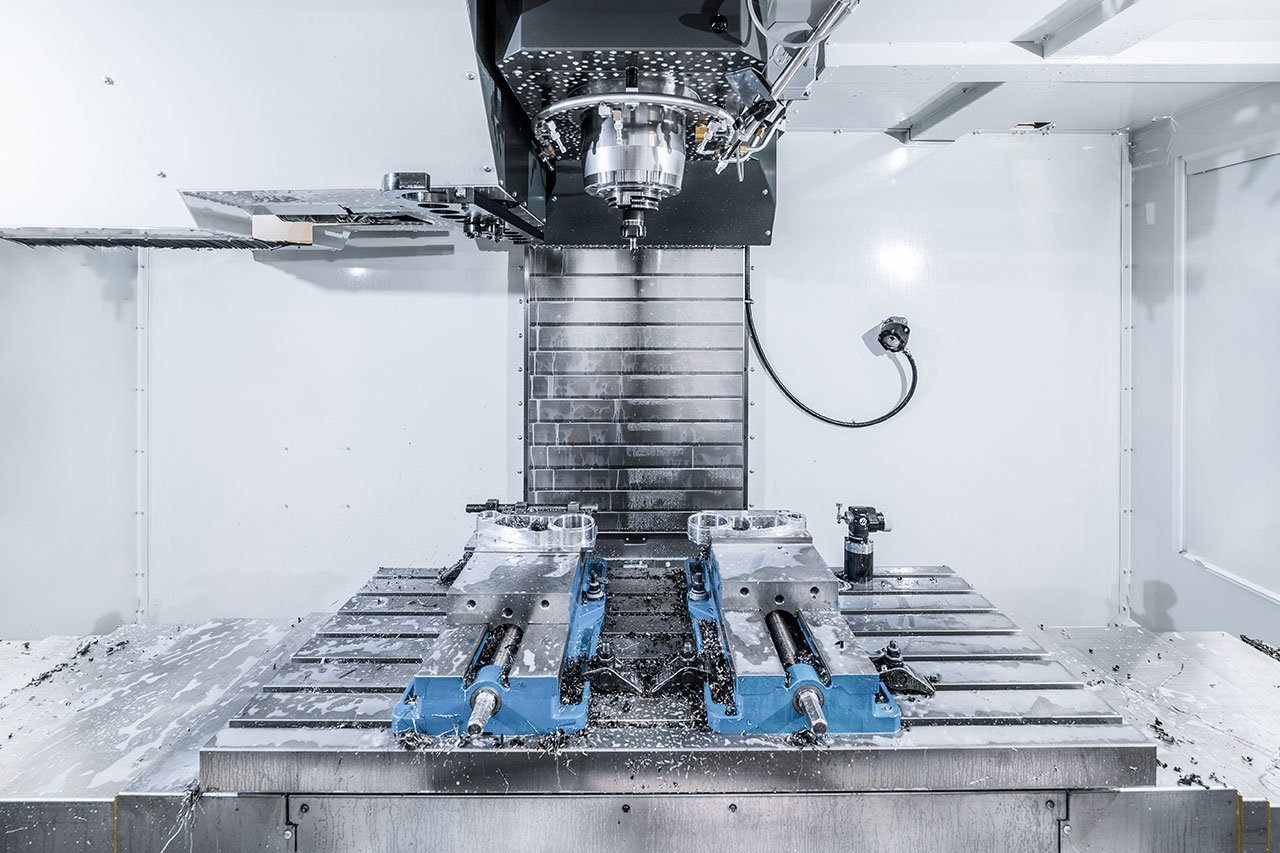

Simple calculation is markup 1 owners salary benefits annual earnings goal annual service hours machine labor overhead cost per hour. Add in electrical tooling air saw and a handful of deburring equip. 3-axis machines including CNC milling machines which cost around 40 per hour to run and CNC turning machines which cost about 35 per hour to run.

CNC machines arent inexpensive. These milling machines being mostly in the 3000-10000 range. Scaling a CNC Precision Shop for Growth.

The benefit of a single manual machine is low overhead which can help you get into the business and start to build some capital for the eventual CNC investment. Nevertheless there are ways for business owners to keep their startup costs relatively low -- and its possible to start a CNC machining business for very little. Press the Calculate button to figure out the machines hourly rate.

The prevailing rate structure must allow you to recover your operating expenses. Converted to a percentage for example this will come to something like 120 percent basically adding 20 percent profit to the cost. Videos you watch may be added to the TVs watch history and influence TV recommendations.