Types Of Holding Tools In Workshop

Dies are the cutting tools used for making external thread.

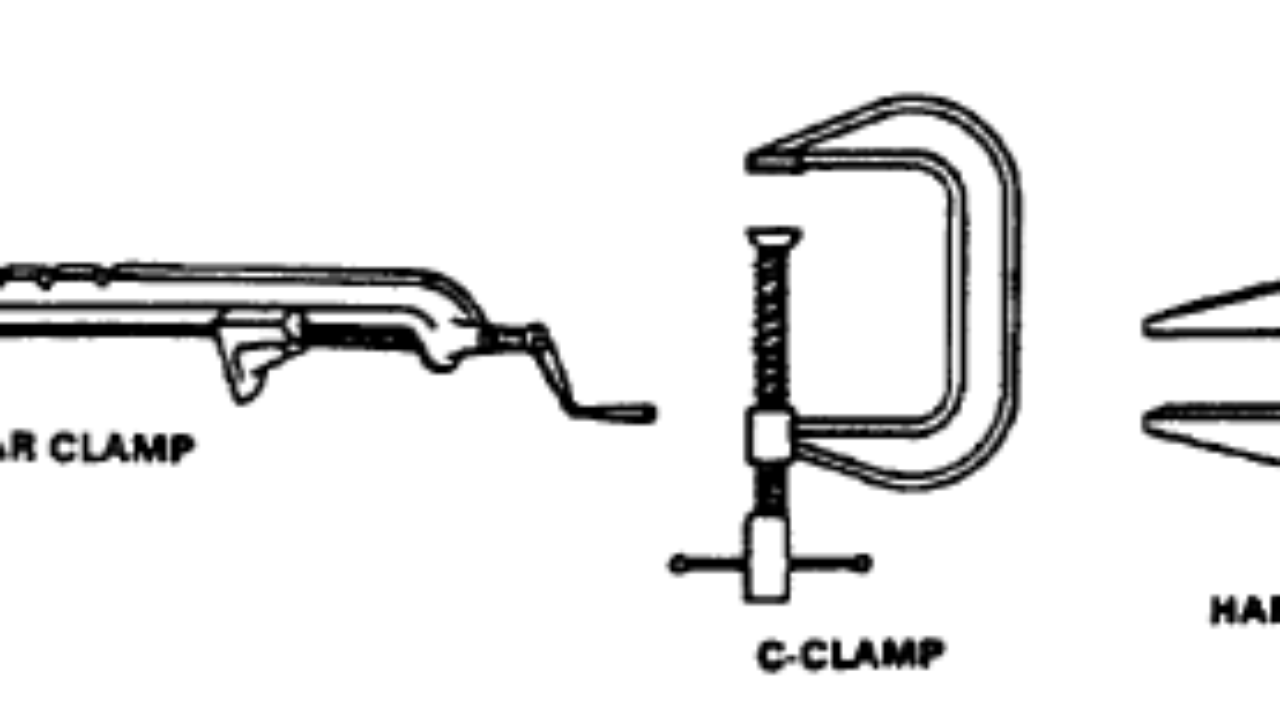

Types of holding tools in workshop. The specimens were taken and that you will see in the engineering workshop. There are other similar types of such clamps named as rack clamp screw clamps light duty parallel clamp adjustable bar clamp G or C-clamp and double bar clamp which are useful for holding different sizes and shapes of wooden jobs. Dies and die holder 146 Bench Drilling Machine.

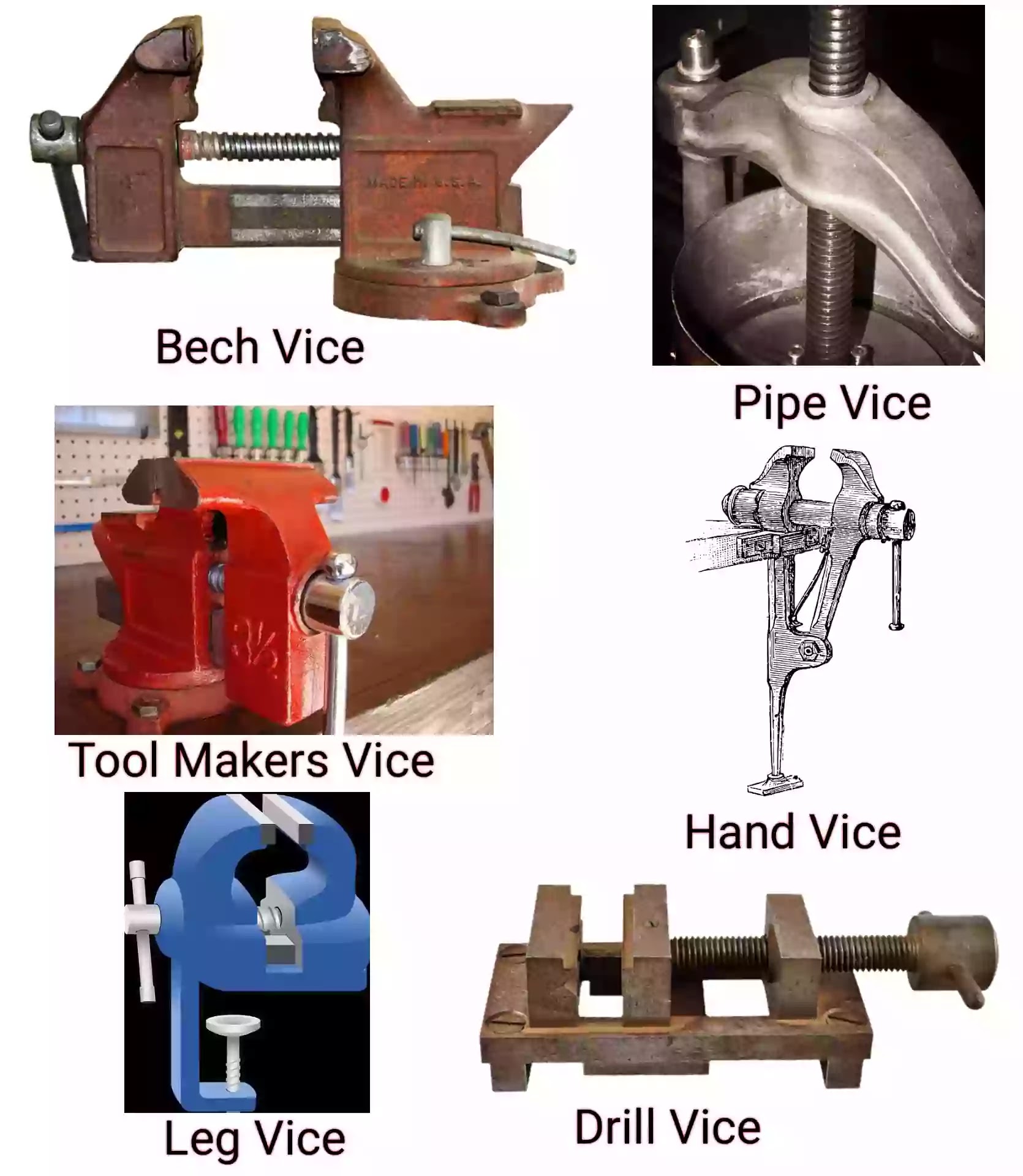

Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting. A4 Machinist vise is a work holding tool for machining activity. When the vice handle is turned in a clockwise direction the moving jaw forces the work against the fixed jaw.

Copied from Basic of Manufacturing Processes and Workshop Technology by Rajender Singh. The power drill is a very versatile tool used both commercially and on a workshop level. They are 3 types of Marking tools used in the fitting workshop and are as follows.

Toolmakers vice The Detailed Explanation of Work Holding Devices was HERE 2MARKING TOOLS. Hand Vice 5. Its uses may seem simple limited to drilling holes and inserting screws or fasteners but the drill is backed by a plethora of attachments and drill bits as well as settings for speed power and torque.

Holding tools are also known as Work Holding devices in the Fitting workshop. Take a look at the hydraulic wedge spreaders we have on offer by clicking the button above. Marking tools in workshop are Surface GaugeSurface PlateMarking TableScriberPrick PunchCenter PunchDividerTrammelBevel Square.

The bench vice is a device commonly used for holding the work pieces. Hand Tools for Workshop 5a. Some considerations about a medium-length workshop.