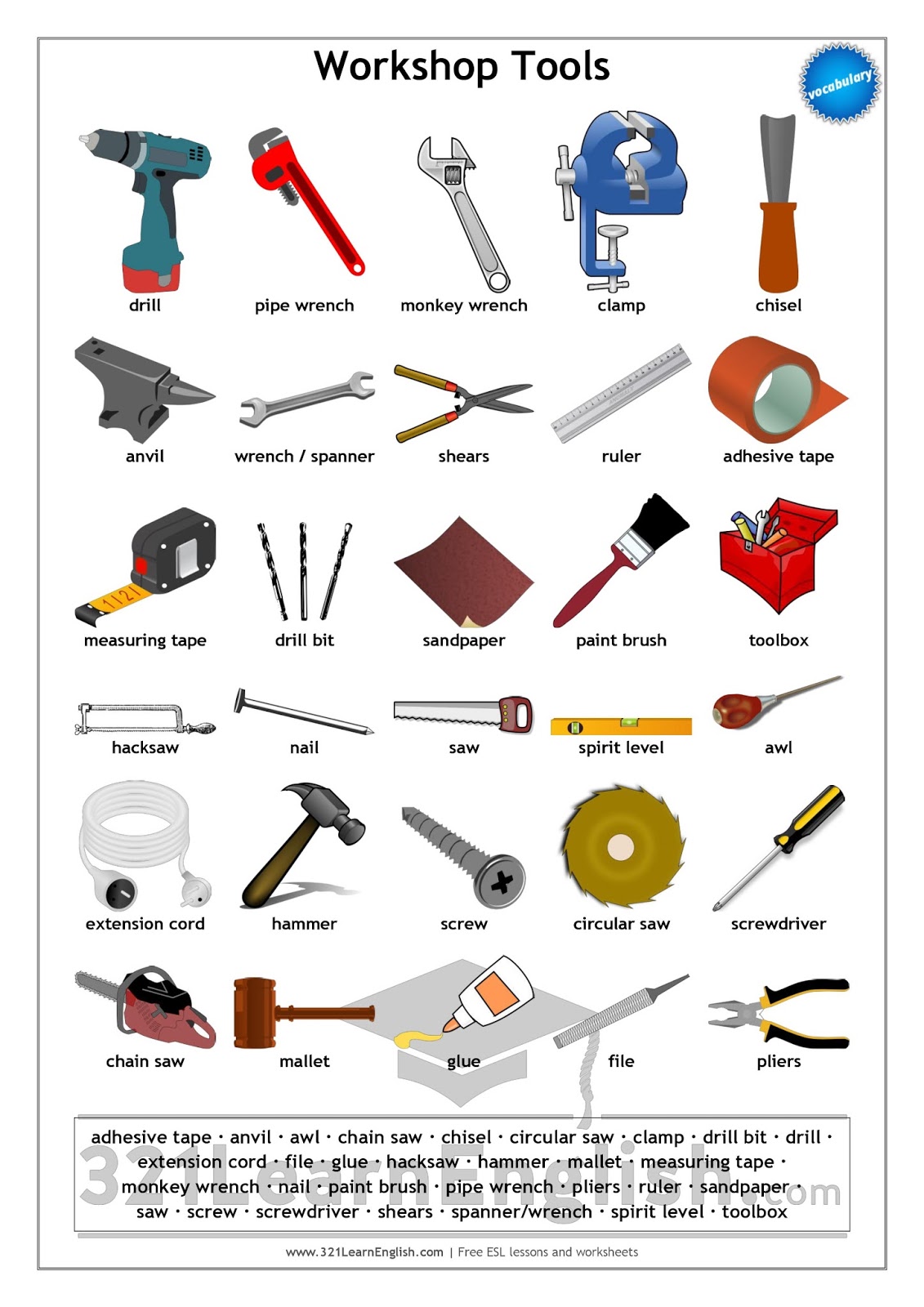

Study Of Different Types Of Hand Tools Used In Workshop

They also absorb shock force which occurs when an item is dropped which stops the worker being pulled down at the same time which is particularly helpful if you are working with heavy workshop equipment.

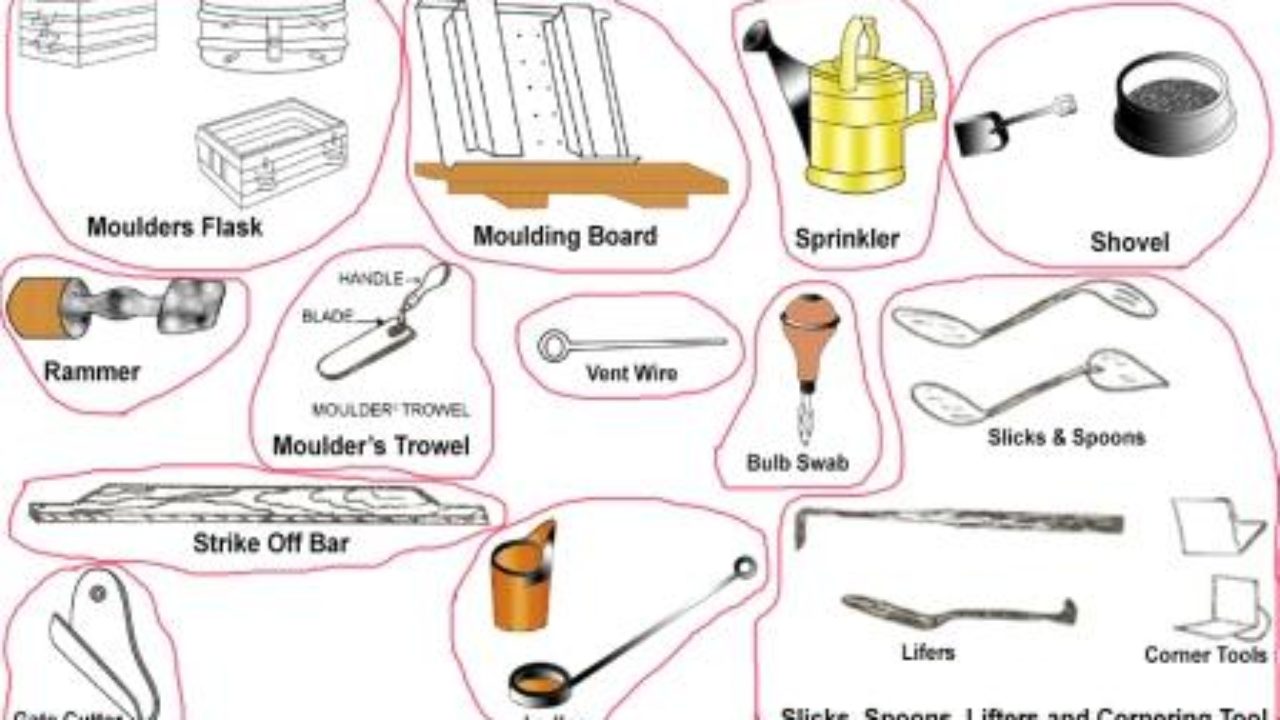

Study of different types of hand tools used in workshop. Power tools used by Builders are briefly described. Holding tools are also known as Work Holding devices in the Fitting workshop. No place is this more important than in the machine shop.

Holding Tools used in Engineering Workshop. Richard Sennett Introduction Having just the right tool for the job makes all the difference in getting the job done quickly and correctly. Different types of hammers hard and soft mallet sheet and wire gauge necessary allowance required during job.

Remove sharp edges finish fillets and other interior surfaces Fig124Sharp cutting teeth are provided on its surface for the purpose. The ideal type and model of a power tool is unique to each carpenter but generally all of them will possess the following in their work environment. Farm Jacks What farm jacks are used for.

On a separate piece of paper classify the different kinds of hand tools according to their specification in Consumer Electronics Servicing. They are rarely required and can always be borrowed from your local mechanic. Their uses general characteristics attachments and safety and operating features are outlined.

The Various Work holding devices are. The power drill is a very versatile tool used both commercially and on a workshop level. This chapter looks at fourteen different categories of basic machine shop hand tools and how they are used.

Jewelers Screwdriver Set 8. It is used with a hand drill. Soldering Tool Stand 9.