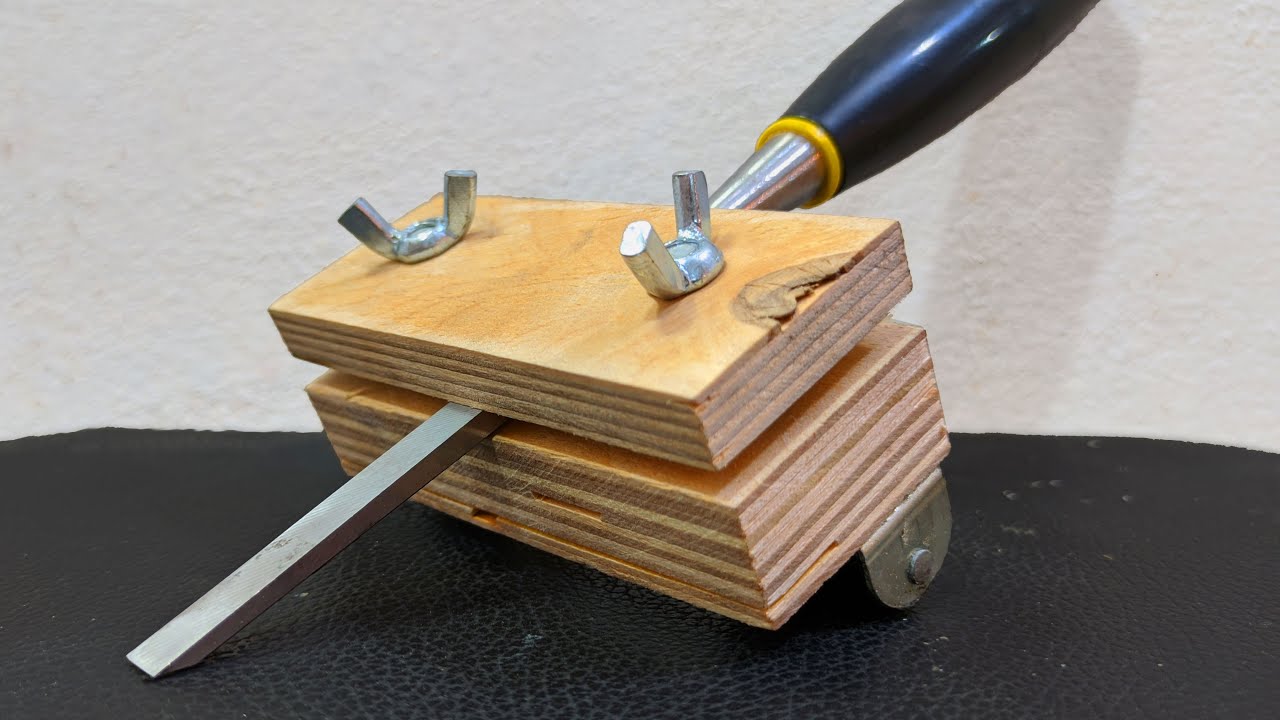

Making A Wood Turning Chisel Sharpening Jig

Chisels gouges bowl gouges spindle gouges carving tools woodturning scrapers parting tools block plane irons and more.

Making a wood turning chisel sharpening jig. I forgot to take a picture of this step but you can see them in this picture as well. It can be a nightmare to try and sharpen wood turning chisels such as bowl spindle roughing gouges and you can easily ruin your expensive tools if your not careful. See more ideas about lathe tools wood turning woodturning tools.

The first is a template to set the jig locking angle. The scraper is one of the easiest tools to sharpen the only technical part is the angle most literature suggests using a 70 degree angle. After a bit of practice the sharpening becomes quick and easy.

The long tubes should have 2 holes drilled in the top. Now turn the grinder on and lower the tool onto the wheel. By adding stops at the most common measurements you can skip the guesswork and get the right angle every time.

By building a chisel sharpening jig or chisel sharpening station if you prefer you can get the process done much quicker. Just ignore those bits in the middle. Its design will depend on the grinding jig.

Adjust the jigs leg per the manufacturers instructions set it in the V-rest and then slide the rest out so that the center of the bevel rests on the center of the wheel. I screwed 2 sections of 10 oak to the ends of the bottom board this would be for supporting the outside edges. Deulen Planer Jointer Sharpening Jigs-Sharpening Jigs.

So once gain adjust the angle of your tool rest to where the angle will be around 70 degrees and start grinding. Then I cut 6 lengths of Oak at 10 each. Same as any craft woodturning demands a strong foundation in the basics knowing the wood properties tools techniques and most especially design techniques or considerations.