How To Sharpen A Metal Lathe Parting Tool

Maximize Cutting Tool Stiffness.

How to sharpen a metal lathe parting tool. Even though the overall relief angle might be 8 its the almost microscopic angle at. You may have an old-fashioned stone wheel or more likely youll use a modern bench grinder. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner.

Point it invariably rounds the edges blunting the tool and causing rubbing just below the actual cutting edge. Need to buy a new cutter now. Grinding angles start on next page ROUGHING GOUGE.

Dip the tool in coolant frequently to keep it from overheating and annealing. What is the procedure for sharpening HSS general-purpose lathe tools. Bits to be sharpened.

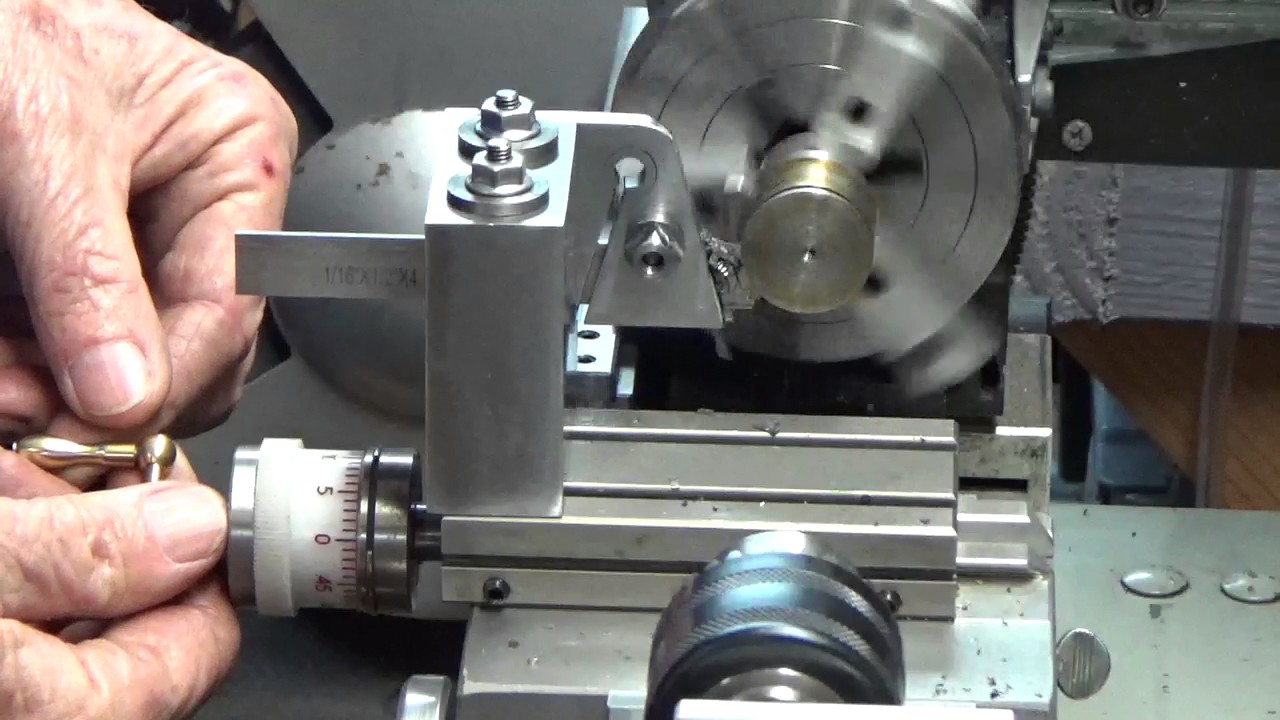

If using HSS parting blades grind andor hone the cutting edge to ensure its sharp. Turn the parting tool over and do the opposite side for the same amount of time. Shown below is what Ive put together to achieve the level of accuracy desired.

In general the method is to use either a grinder or belt sander and then finish with a hone. In this example we are making a normal right handed tool for the lathe. The grinding rest was tipped to give the required side clearance relief and the fence adjusted to give the side cutting edge angle.

A demonstration on how to sharpen a lathe parting tool. If using an indexable part-off tool check that the cutting insert is in good condition. Used for roughing spindle stock only do NOT use on bowls.