How To Setup A Parting Tool On A Lathe

Never assume the tool is setup properly just because it was in the lathe.

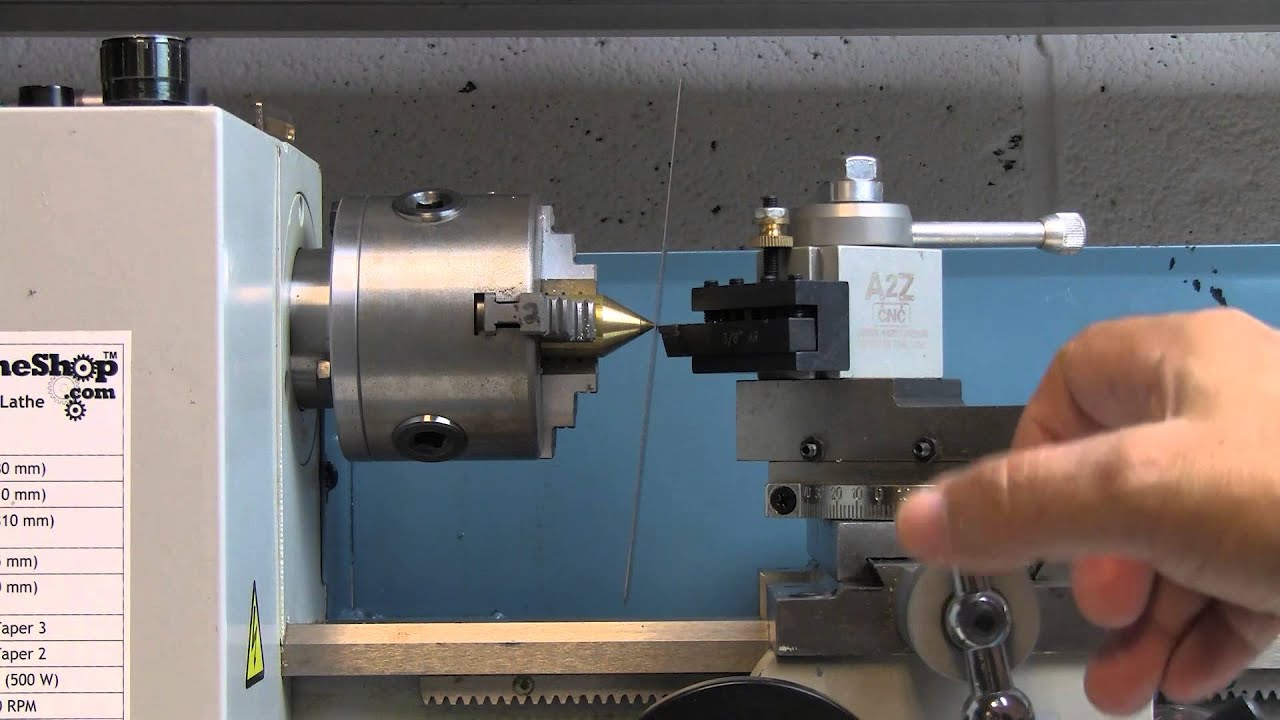

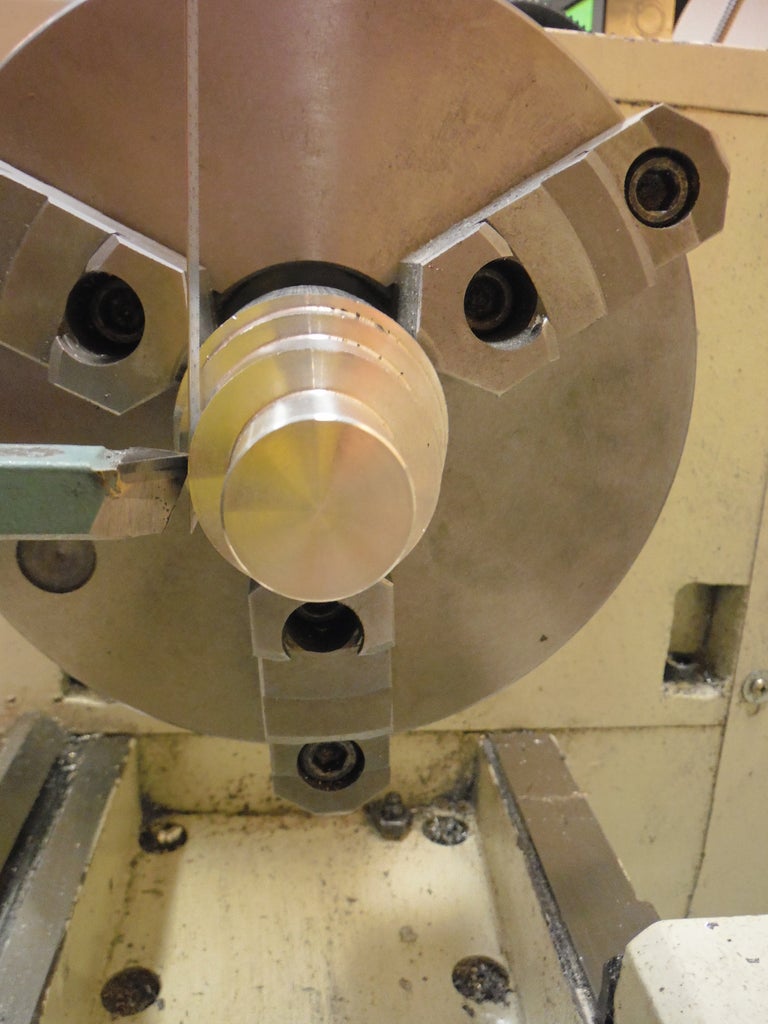

How to setup a parting tool on a lathe. This is two parts. I took a practice cut on some 1 diameter aluminum rod. Parting is done with a special tool.

1 x Key insert remover. Not a very good shot but it does show the thickness. Edges faceedge need to be 90 so must be held square to wheel.

Then turn the workpiece round and face it to the right length. Feed by hand and slowly at first--you will develop a feel for feed rate 4. Hollow the interior of the bowl and finish both sides of the bowl.

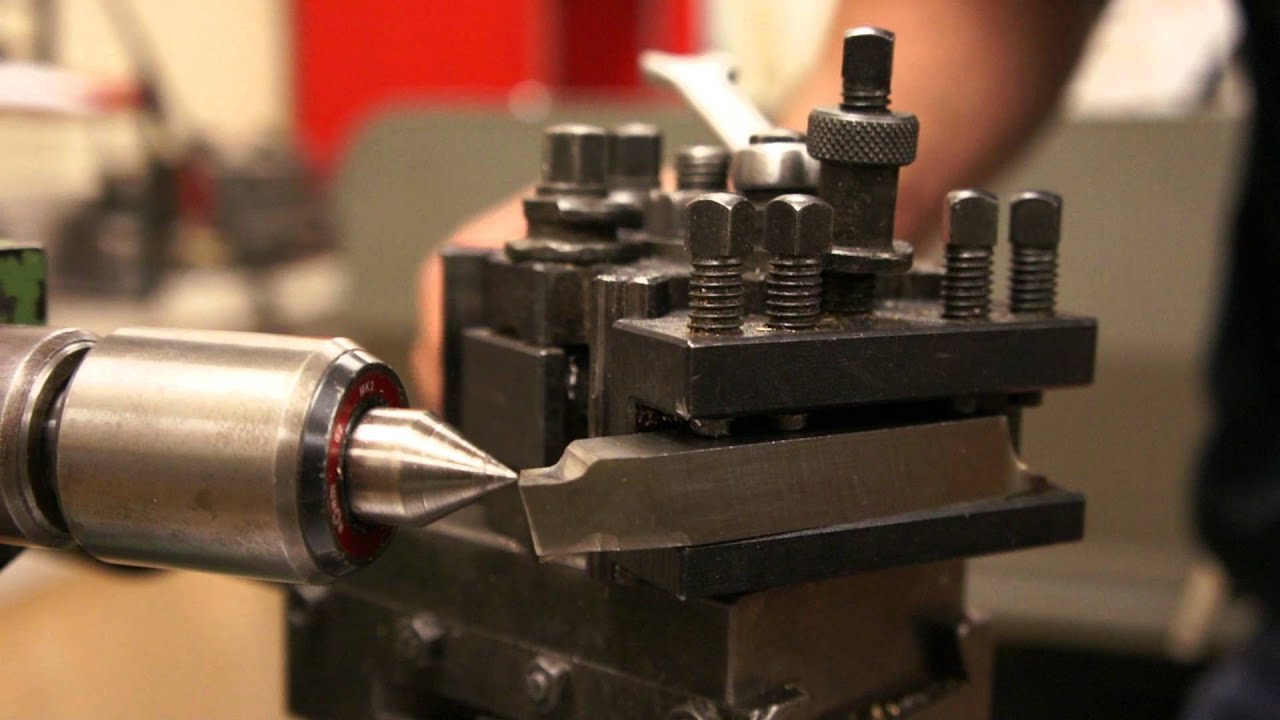

For an optimal parting tool set-up use a tool holder with a short overhang to avoid vibration. This video covers how to properly grind the tool how to set the tool so it is ri. When machining with long overhangs it is especially important to mount the bar correctly to ensure enough clamping contact.

There are several options. With the tip of the tool just beyond the surface of the workpiece turn on the lathe. Be sure tool is sharp 3.

Load your cylindrical part in the chuck of a lathe when you tighten the chuck rotate the part with your hand lightly until it cant move anymore to center the turning part. Parting off bowls and lids When turning a bowl on the lathe and holding it by a tenon in a multi-jawed chuck the parting tool can be used to part the bowl from the lathe. Parting tools are used for parting through spindle stock and several other operations.