How To Open A Cnc Machine Shop

And starting out you better know how to fix your own stuff never had a.

How to open a cnc machine shop. Perhaps they could not be more different. For example machining offers a predictable link between input and output. This will be ran by myself.

A particular job on a particular machine tool ought to have a reasonably predictable cycle time. For a shop to go paperless its machine operators must have instant digital access to all information normally found in a job traveler. Ask your current customers for referrals to you and for names.

A specialty that you are absolutely better at than anybody else. To accomplish this shop management must install tablets networked computers or other digital devices at workstations throughout the facility connecting the operators to the latest. Starting Your Own Machine Shop.

Nobody has done what Titan has done in this amazing industry. Business-to-business machine shops can be divided into two categories. Job shops and product.

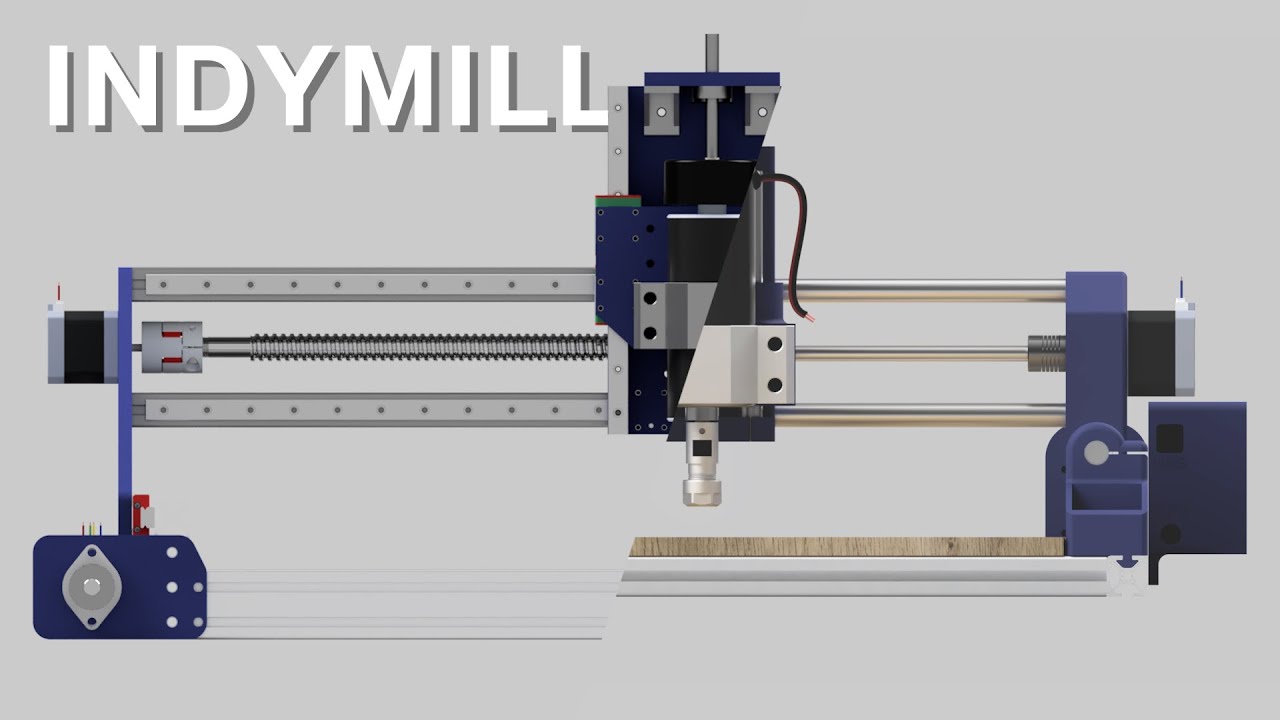

The first shop rentedleased shop was the corner of a 1600sqft wood shop literally just the corner. Looking to start your own CNC business. Have some few machines and from there build capital.

A frequent question is How do I begin For the benefit of anyone interested in starting such a business I offer some ideas to consider. After you must have analyzed the risks of converting your home garage into a CNC machine shop write a business plan and make sure it incorporates all the risks. First test the market and your team by starting small.