How To Manage A Cnc Machine Shop

75000 - 85000 a year.

How to manage a cnc machine shop. Delays in production can lead to increased costs and missed deadlines which ultimately can lose a business clients. The CNC machine shop is more efficient when all the personnel work together. Tipp City OH 45371.

Continuous improvement is necessary but managing the rate of change is important. Depending on the capabilities of the CNC machine shop they can concentrate on specific industries. Excellent Benefits and Flexible Schedule.

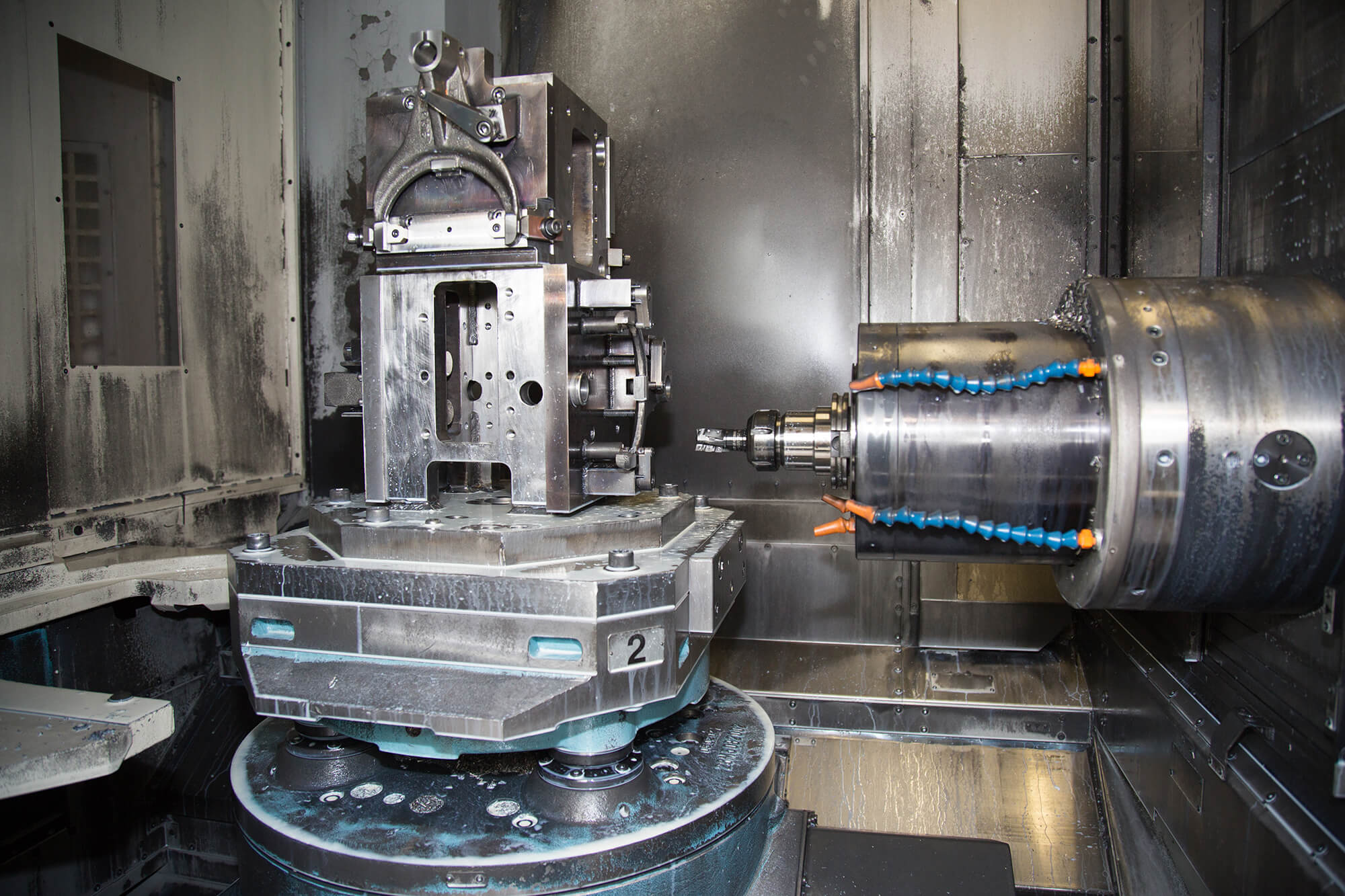

Efficiency helps make production run smoothly and eliminates wasted time. How digitalization has changed the machine shop Computer Numerical Control became commonplace in the latter half of the 20th century changing machine shops forever. It should go without saying that CNC people directly affect the productivity of the machine or machines on which they work.

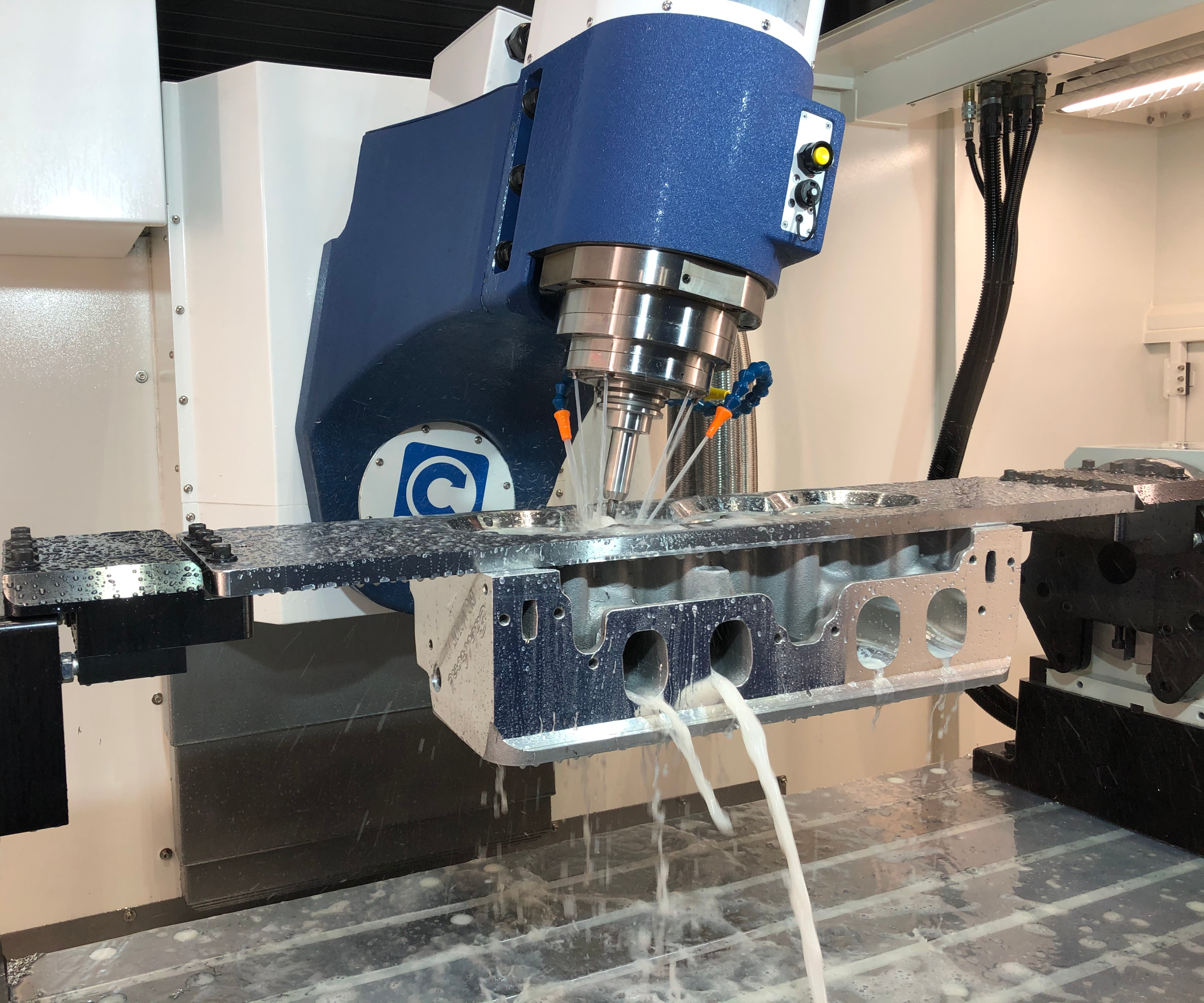

A CNC machine shop is a high profile manufacturing facility that will deliver your orders if you need metal plastic and other parts for different machine components. Individually none of these changes is. When employees manage the machinery well there is increased production and less wastage.

CNC Programmer and Machine Shop Supervisor. Try doing an inventory of your staff and see whether youve got all the bases covered youd like to have. Every person working on a project has his own role and should garner respect from his peers on site.

Here are some tips and suggestions for small CNC machine shops to continue growing their businesses. Never allow the use of compressed air for cleaning skin and. However a workshop does not need to be messy and will function much better if it is.