How To Make Your Own Cnc Wood Router

With 20 inches wide the kinetic sculpture can run several hours by a single winding.

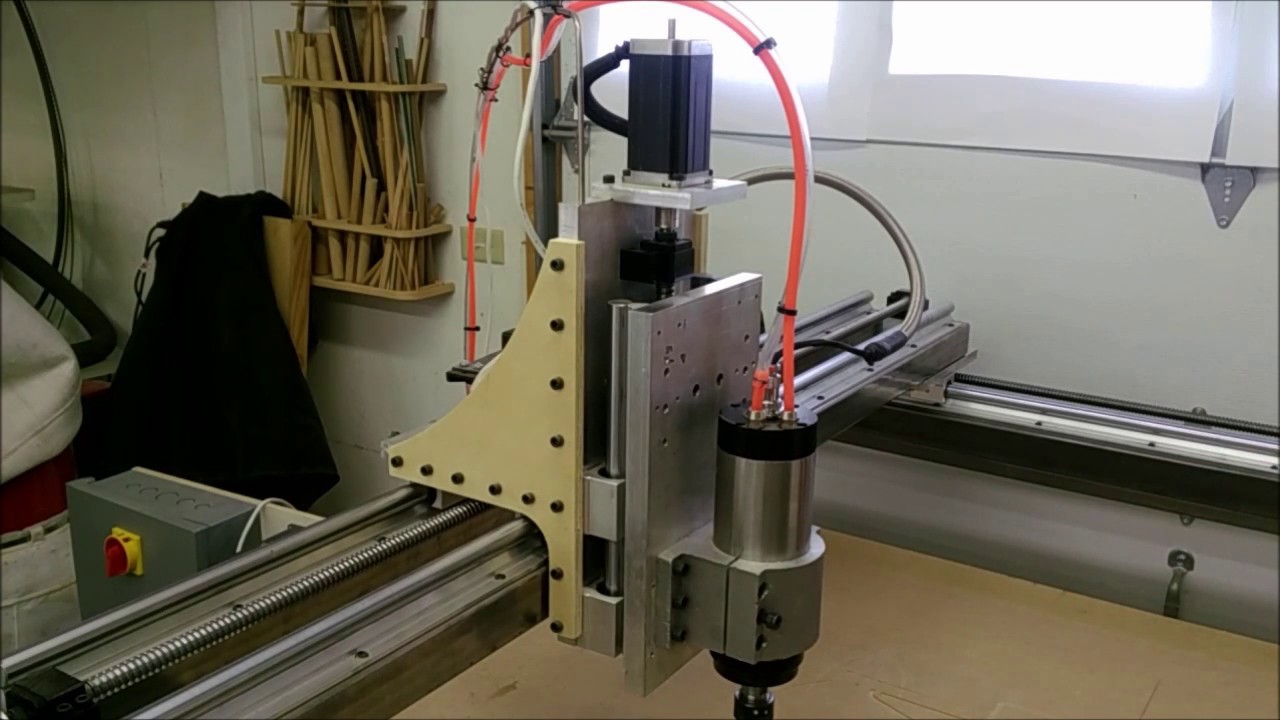

How to make your own cnc wood router. There are 3 steps to the project Construction Software Manufacture. I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

By using calipers dial indicators and a machinist square you will need to measure precisely. Drill and tap some mounting holes in the edge of each bearing and. Get a website as soon as you can and run a few paid ad campaigns.

The next and most expensive step is the electronics. Musical instruments have high requirement on precision and aesthetics. Most importantly leverage your new and existing offline connections to get more clients.

Almost every CNC router hobbyist can create this wonderful project without the need for engraving metal parts. It would be just like a professional is next to you guiding you every step of the way. A set of metric and imperial hex keys 316 and 5.

The quality of your fittings bearings and other motion hardware is important. Making musical instruments is also a good way to run your CNC machining business. If you are building a 3 axis CNC router you should buy a kit consisting of three sets of linear rails and two linear bearings per rail.

Before assembling your machine ensure you have these tools. Like many CNC router projects the wood needs to be flat and sanded down with grade 180-240 sandpaper. Timing belts rack and pinion and drive screws.