How To Make A Parting Tool Holder

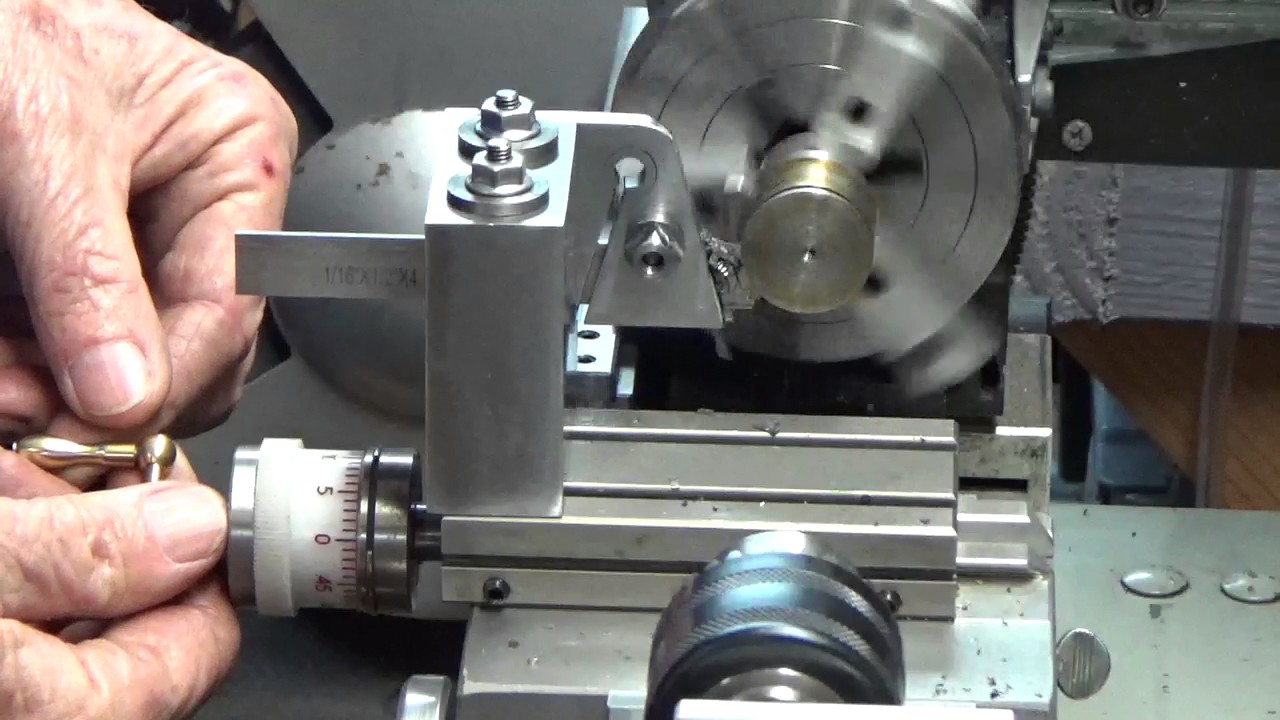

To truly advance parting off operations it is not enough to develop a new toolyou need to develop the method for using it.

How to make a parting tool holder. So I thought I would make my own parting tool for woodturning. To ensure the parting tool is perpendicular to the face of the chuck you can use a 1-2-3 block whose surfaces are ground to be parallel to one another. The easiest thing to use was a part.

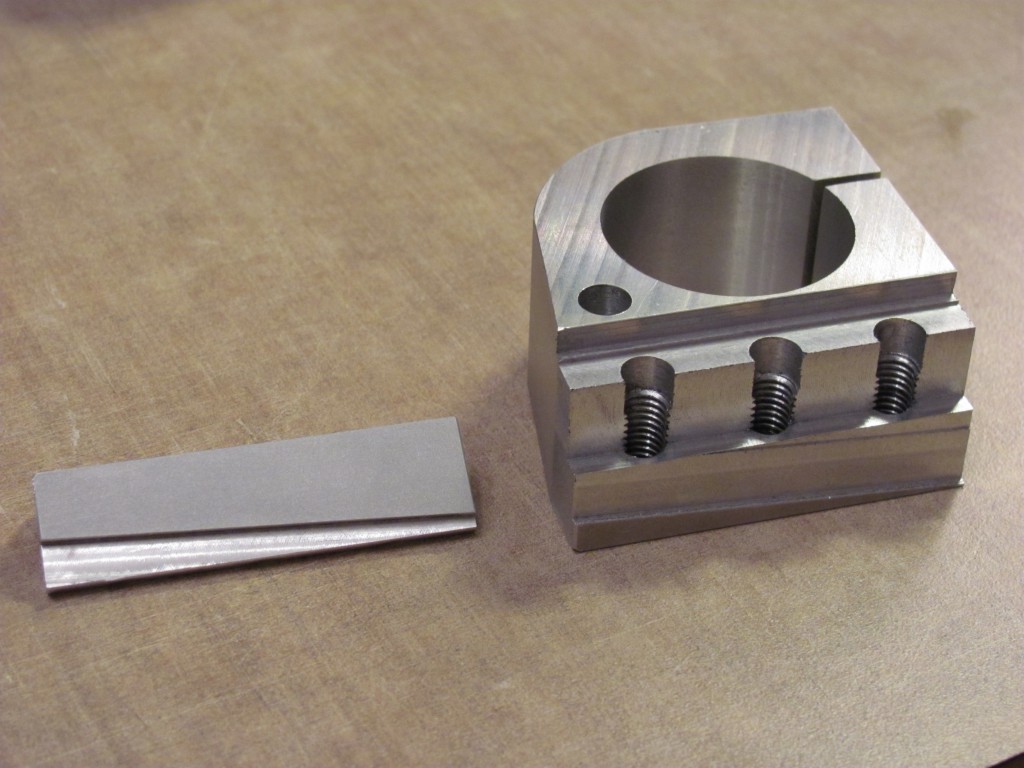

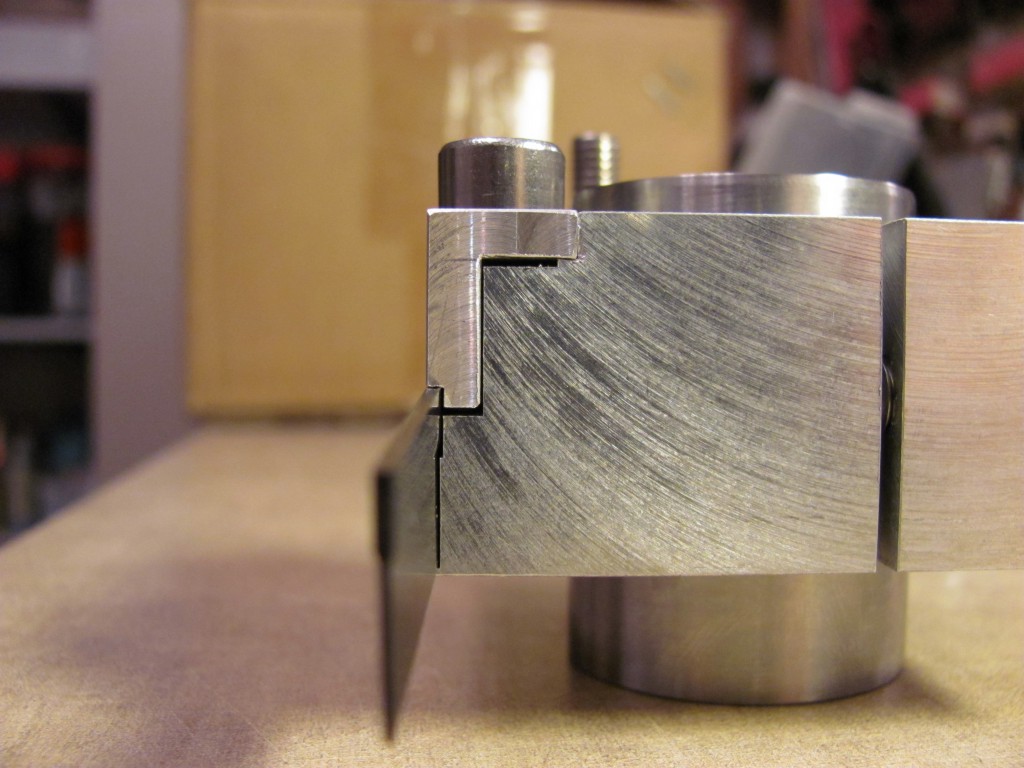

I needed a parting tool that would give a little so I based my design on designs I found on the internet. Leave one side with no slot. Its made from scrap.

No matter what holder I make it still has to be adjustable so I could center the blade. The only way this happens is when the lathe is fitted with an American style toolpost. C any other designs that basically does the same thing like parting from the opposite side of the spindleetc.

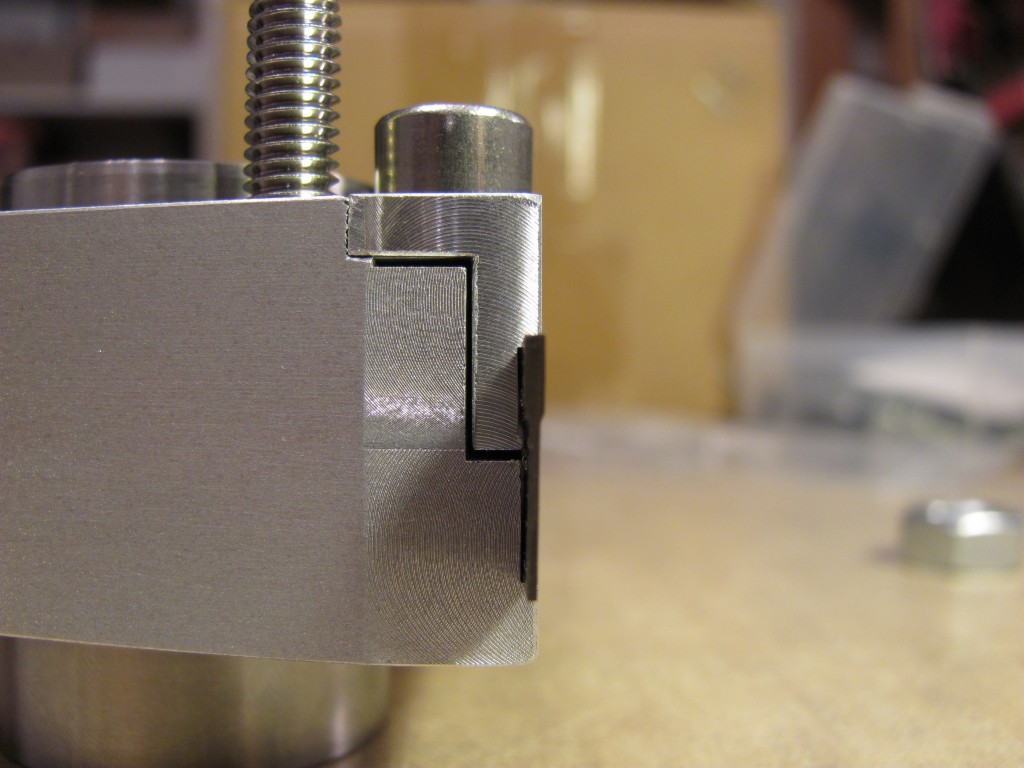

The problem of snatching with HSS parting blades. I had a short production run I needed to finish and part of the process required a small groove at the end of the piece. The blade holder and a bar I milled and drilled and tapped 14-20 to bolt to the blade holder.

I find that locking my carriage is an essential step to take in order to maximize rigidity. Open out to 1 dia. Loosen the tool post align the edge of the toolholder flush with the 1-2-3 block and re-tighten the tool post.

Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting. Fig cranked parting tool holder. This is two parts.