How To Grind A Lathe Parting Tool

If you break off the end you just grind a.

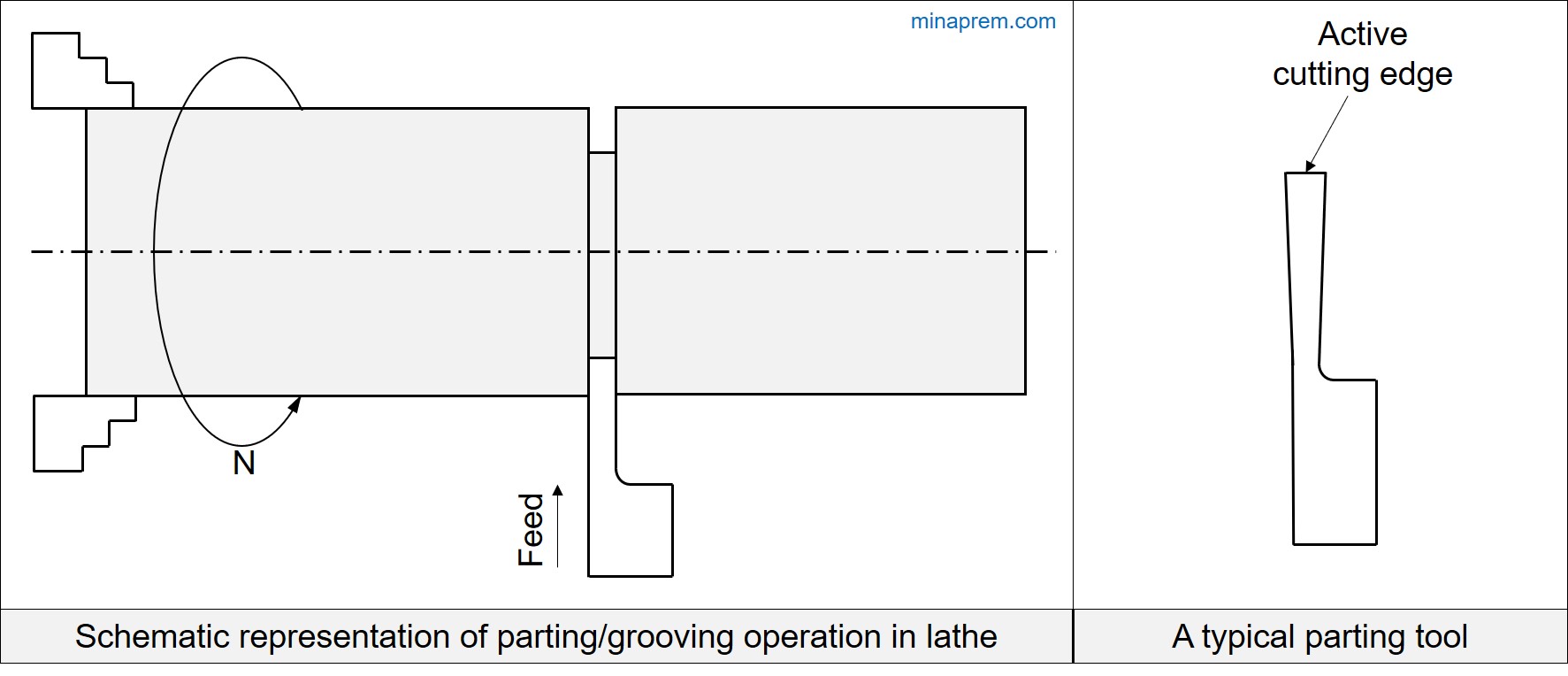

How to grind a lathe parting tool. Inspect the parting tool closely before using. Make sure your tool is exactly perpendicular to the axis of rotation as well. Parting is one of the most misunderstood machining operations on the lathe.

If using HSS parting blades grind andor hone the cutting edge to ensure its sharp. For our second project we were given two new 38 lathe bits and had to learn to grind a turning tool parting tool facing tool and a threading tool for 34-10 ANS threads. The grinding rest was tipped to give the required side clearance relief and the fence adjusted to give the side cutting edge angle.

Then I used the disk sander to round off the corners and the wood end of the parting tool. Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. 1 Its difficult to sharpen the bevels of a parting tool and arrive at the correct side profile with the ears leading the nose.

My most immediate need is to grind a single point cutter for ACME threads. Im assuming youre talking about your average HSS parting blade including P-type If you grind the top of the blade the tip becomes lower than the original top. Edges faceedge need to be 90 so must be held square to wheel.

Even so this little tool is tempting because grinding a parting tool from a tool blank is a pain - since so much metal must be ground away - and parting tools get dull and break easily. If youve used the bench grinder recently youll want to dress it removing the old bits of debris caught in the stone. Sharpen square- or round-nose scrapers on a bench grinder.

If using an indexable part-off tool check that the cutting insert is in good condition. I then cut the end of the blade off to square it off and I cut and ground down the teeth. The flat that is currently ground into the tool will register itself on the platen if your right hand is relaxed.