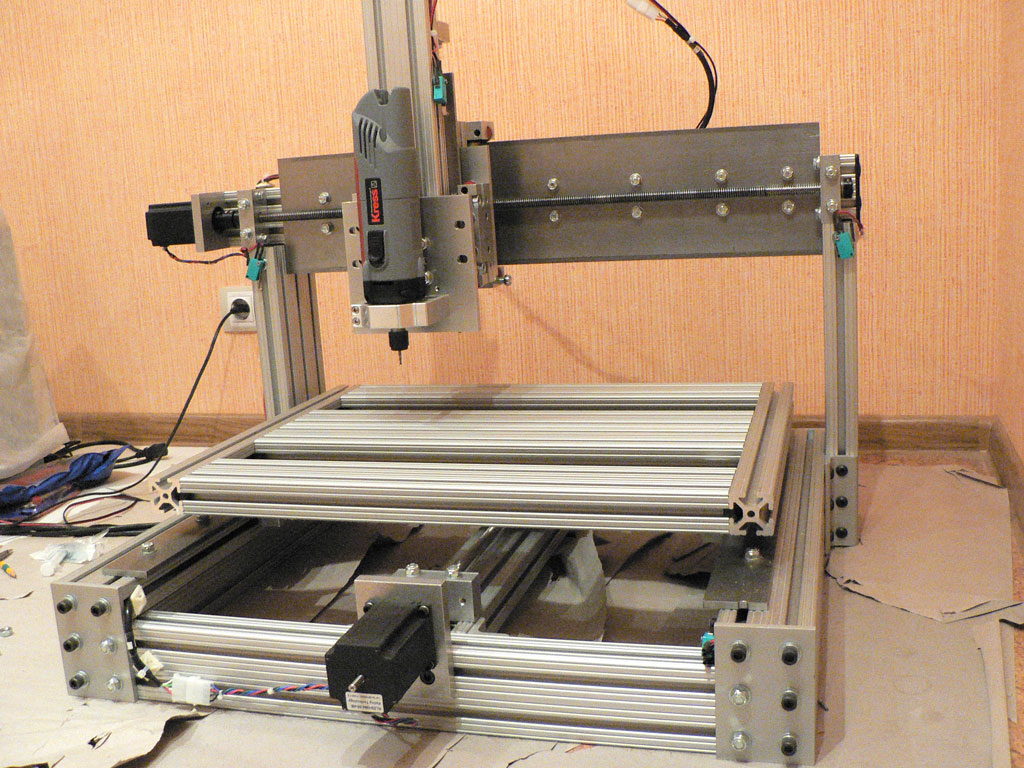

How To Build A Wood Cnc Machine

A few items that went into the 8000 cost of the machine.

How to build a wood cnc machine. 85 Thread a 8 nut on each machine screw with a washer between the nut and the trolley. Building your own 3-Axis CNC router is both fun and educational. They are primarily used for commercial projects.

Once the tool is fixed in to place attach the MFD Sheet and tool to the drawer sliders. But now many hobbyists turn to it for home projects as well. It allows you to cut exact designs out of your material quickly.

84 Feed the machine screws through the mounting holes on the trolley. A Length of wood needs cutting to add to the bottom of 300mm lengths of the Y-Axis. 82 Attach four 2 machine screws to the motor mounting holes with washers against the faceplate 83 Thread on a 8 nut and a washer to each machine screw.

In this video I show you how I built my DIY CNC machine. Its important to make sure the Threaded Rod the Drawer Sliders are all level. Orient with the collar facing the motor and approximately 116 from the face plate.

Now add the threaded rod threw the 2 bearings. Measure and cut a small sheet of MDF to fix the tool to. Discover how easily you can build a powerful Ultra-Precise CNC Woodworking Machine --Hobby versionDesktop versionProfessional wooden andor metal base ve.

A CNC Computer Numerical Control Router is a machine that uses a computer and coding to make precision cuts into wood metal plastics and other materials. Nevertheless the key steps to build your own CNC machine will generally be as follows. The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors.