Explain The Different Types Of Cutting Tools

These are two of the most prevalent milling operations each using different types of cutters the and mill and the face mill.

Explain the different types of cutting tools. In bulk garment manufacturing multiple fabric layers are cut at a time by means of cutting machines. Built-up edge means the adhesion of work material on the rake face of the cutting tool near the cutting edge. Different types of cutting machines and equipment are available for cutting fabrics and machines are used as per requirement and production volume.

Machining cutting tools range from rough cutting equipment like chop saw or grinder to programmable production oriented machines like the metal mill. While some cutting tools require some type of human interaction to perform a function others might be completely computer operated. It occurs frequently while machining softer or ductile metals at lower cutting speeds.

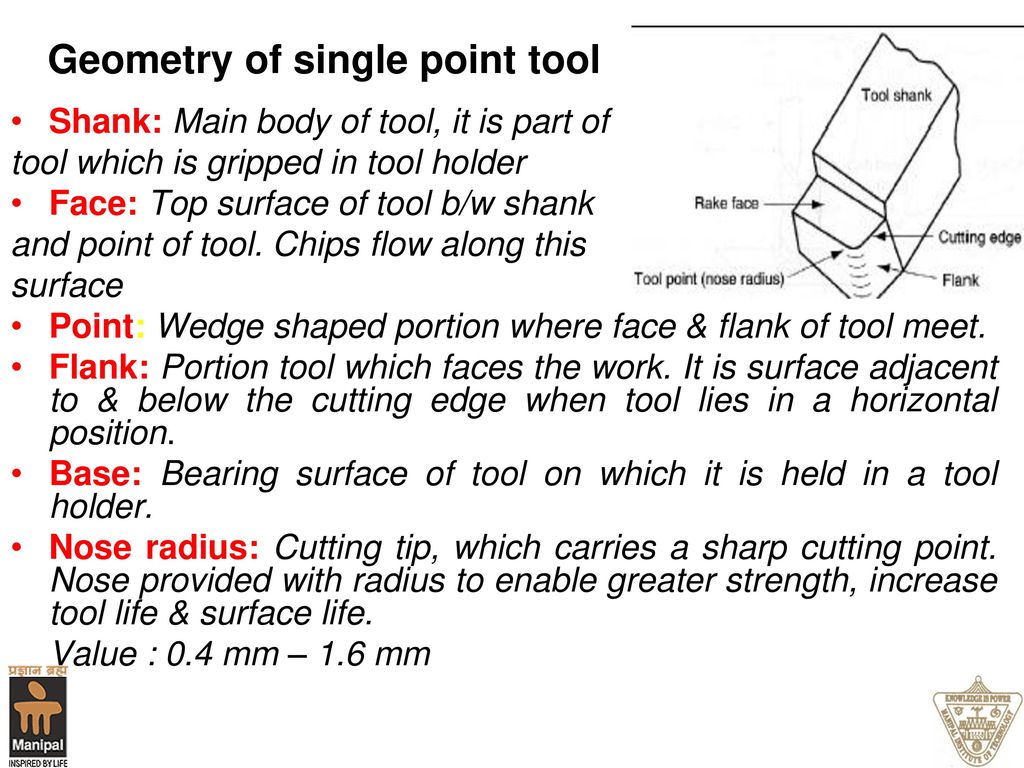

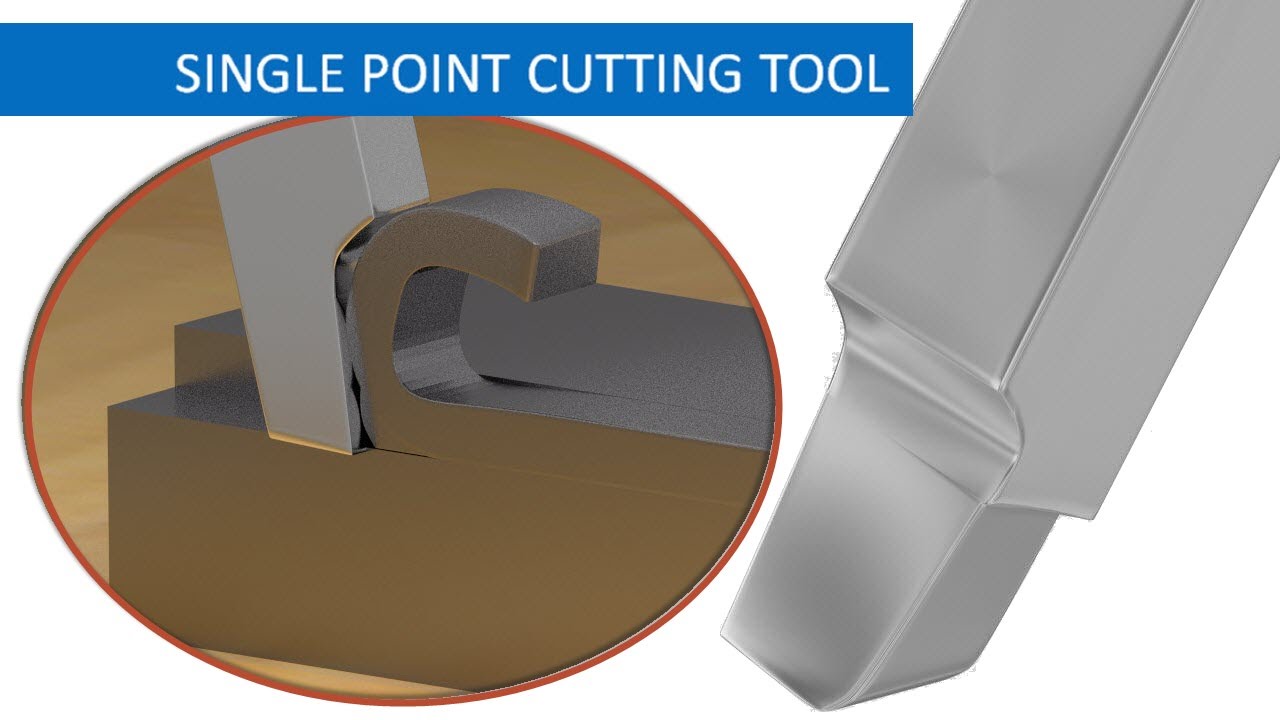

Written by Amrit Kumar in Manufacturing Process Single Point Cutting Tool is a tool that helps to perform several operations like Turning Facing Producing Flat surface on Lathe Shaper Planer Machine. However the tools are mostly made of artificial single crystal diamond. Slide and face cutter.

Forms of Tool Wear. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter whereas face milling is used for horizontal cutting. Other types of machining tools might include fly cutters and reamers.

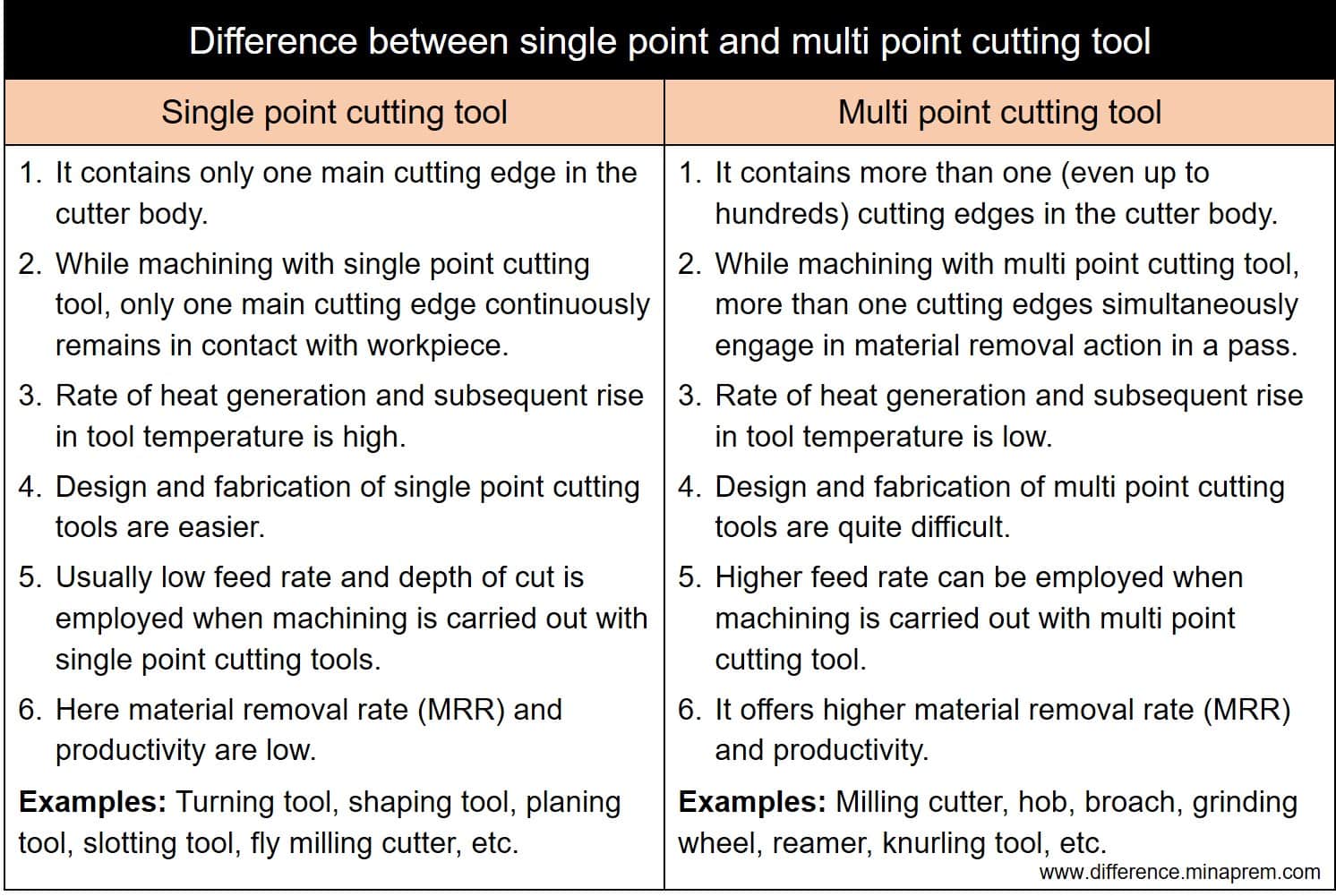

For example low carbon steel aluminum and copper. There are two types of cutting tools in this category Single-Point Cutting Tool. The blade will typically display wood bi-metal or metal.

Single -Point Cutting Tool. Its cutting speed is about 10 mm and highest temperature up to which it can work is 200 250 degree centigrade. Flank and crater wear are very common type of wears.